What is total viable count in water testing and why is it important?

Editors note: This blog post was originally published in August 2020 and has been updated with more information.

Water that is supplied to buildings from a mains water supply can contain bacteria. It is the responsibility of water companies to remove all harmful bacteria from the water before it is piped to homes and businesses so that it is safe to consume. However, some bacteria, generally at very low levels, can enter and remain in our domestic systems, and if the bacteria are allowed to breed, it can cause a problem.

A general bacteria test looks at the overall number of microorganisms present in the water that are able to grow. This is known as a total viable count (TVC).

What is TVC in water testing?

Total viable count (TVC) is a test that estimates the total numbers of microorganisms, such as bacteria, yeast or mould species, that are present in a water sample. TVC may also be expressed as aerobic colony count.

The results of a TVC test offer an indication into the general level of contamination within a system and the overall quality of the water.

.jpg?width=800&name=My%20project%20(35).jpg)

What’s the difference between TVC and TBC?

While TVC estimates the number of viable or live cells that are capable of growing into distinct colonies, the total bacteria count (TBC) determines the count of all cells both dead and alive.

How is TVC calculated in microbiology?

There are different test parameters for different types of sample.

First, the samples may be incubated at different temperatures depending on the environment being sampled.

For example, samples from a drinking water system should be incubated at 22˚C or 37˚C for 24 hours in accordance with BS EN ISO 6222.

- At 22˚C, the TVC indicates the number of live bacteria per ml of water at ambient temperature, meaning the count will predominantly be composed of harmless bacteria.

- At 37˚C, the TVC indicates the number of live bacteria per ml of water at body temperature, and the bacteria that grow and that are more likely to cause some harm to humans.

Samples taken from cooling tower systems, on the other hand, should be incubated at 30˚C in accordance with ACoP L8, HSG 274 Part 1.

These test conditions are set to isolate the range of organisms that can colonise and cause infections.

Due to the diverse number of organisms that can be found, testing for TVC is referred to as non-selective. This is unlike testing for specific bacteria, such as Legionella and Pseudomonas aeruginosa, which requires the use of selective media.

What is an acceptable TVC?

There is no strict regulation on the acceptable value for TVC in drinking water. However, the guide limits for bacterial levels are that there should be “no significant increase” from the incoming mains supply.

What’s most important is being able to identify any irregularities. This is why it may be recommended that TVC testing is carried out regularly, so that businesses can understand baseline contamination levels and identify any significant deviation from the baseline when it occurs.

What does a high TVC count mean?

A high TVC count, for example 10,000 cfu (colony forming units) per ml of water, signals that there is a high concentration of microorganisms in the water and that the system may be suffering from biofilm contamination. Microbial growth in biofilms may lead to deterioration of water quality as well as bad tastes and odours.

Why do we take TVC samples?

Businesses have a duty of care to ensure their water systems are adequately protected and safe for users. And TVC testing provides an overall indication of the quality of the water. A high TVC, for instance, may indicate poor quality of drinking water. It may have a stale or stagnant taste or odour.

Testing TVC regularly allows for businesses to understand baseline contamination levels and identify any significant deviation from the baseline. When a deviation occurs, it may indicate the need for further investigation and could point to problems in a system.

TVC testing can also be used to assess the efficiency of the water treatment regime. High results in mains fed water coolers, for example, can indicate that they are not being cleaned properly or that the cleaning regime needs to be carried out more often.

Who should measure TVC?

Testing for TVC applies to drinking water as well as non-potable water, such as that used in industry, for example, in manufacturing, food and beverage, healthcare, and pharmaceuticals.

Routine water testing is a key part of drinking water and industrial water treatment. It allows duty holders to monitor for contaminants, corrosion and scale, and identify when a new approach to treatment is required to tackle these problems effectively. TVC is one of the most important things to test for as it gives a good read of the overall water quality and contamination levels.

.jpg?width=800&name=My%20project-1%20(2).jpg)

.jpg?width=800&name=My%20project-1%20(1).jpg)

What does a significant deviation look like?

A count of 50 cfu/ml obtained one month followed a count of 60 cfu/ml the next month would not be considered significant. However, a count of 50 one month followed by a count of 5000 the following month may be considered a significant change to the system.

It isn’t uncommon to find seasonal variations. For example, the TVC may be higher during the summer and it may be appropriate to apply a control measure to reduce the temperature of the system throughout the summer months.

Interestingly, when the coronavirus pandemic forced the nation into lockdown, in many London buildings that were shut down, the TVC was found to be significantly higher than in the same period the previous year. Flushing was not enough to maintain normal TVC levels and Public Health England (PHE) recommended that supplementary microbiological samples should be taken to prove regimes are effective and other actions implemented as required.

What happens if a significant deviation occurs?

When a significant deviation is found, further investigation may be required. This may include sampling for selective organisms or additional water management services. However, with proper monitoring and control for TVC in water, the likelihood of finding a significant deviation is low.

What control measures are there to reduce TVC?

Ultimately, there is no substitute for good engineering, risk assessment and a robust water management plan. However, in the real world we know that sometimes there are buildings and systems with challenges for various reasons.

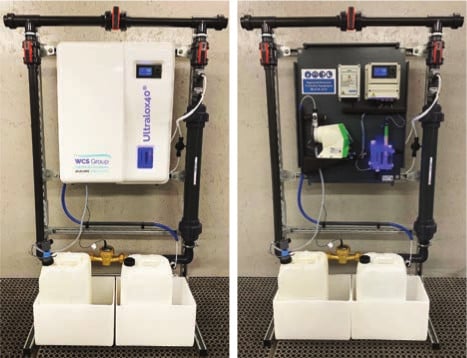

There are many different ways of controlling bacteria if the engineering and the temperature control needs enhancing. One of these is WCS Group’s Ultralox40® solution, which has been proved to reduce stubborn TVC within weeks. It is a highly effective low-concentration form of chlorine and a particularly efficacious fast-acting biocide.

Ultralox40® can be shock-dosed or used as a permanent retrofit secondary disinfection solution. It is suitable for hotels, care homes, schools, offices, commercial buildings, food and beverage manufacturers, leisure centres, and is used widely across NHS sites.

WCS Group provides accredited laboratory water testing and analysis for TVC and other parameters such as legionella, pseudomonas and coliforms. For more information about our water testing services, please get in touch.

Further reading

Here are some more blog posts about water testing that may interest you:

Topics: Water Treatment & Hygiene

Written by Jon Greaves

Jon has progressively worked through operational roles, account management, technical management, and senior management roles over the last 16 years within one of the group companies before moving into the role of Water and Air Managing Director. Jon has experience across multiple sectors of water and air compliance, including district energy networks; data centres; healthcare; food and beverage and facilities management. Jon acted as a corresponding steering committee member on CIBSE CP1 – Heat Networks Code of Practice for the UK released in 2020.