The HiPAF® packaged sewage treatment plant is an ideal solution for rural and remote areas where mains drainage is unavailable.

Serving up to 2000PE population equivalent (PE) the HiPAF sewage treatment systems is adapted to meet your specific needs, backed by continued dedicated technical support:

Process guarantee for the lifetime of the plant

- Minimum of 25 years design life*

Energy saving timer as standard or can be retrofitted into an existing HiPAF®

Low operator maintenance

Manages variable flows and loads

- Ideal for seasonal venues such as hotels, caravan parks and cafés.

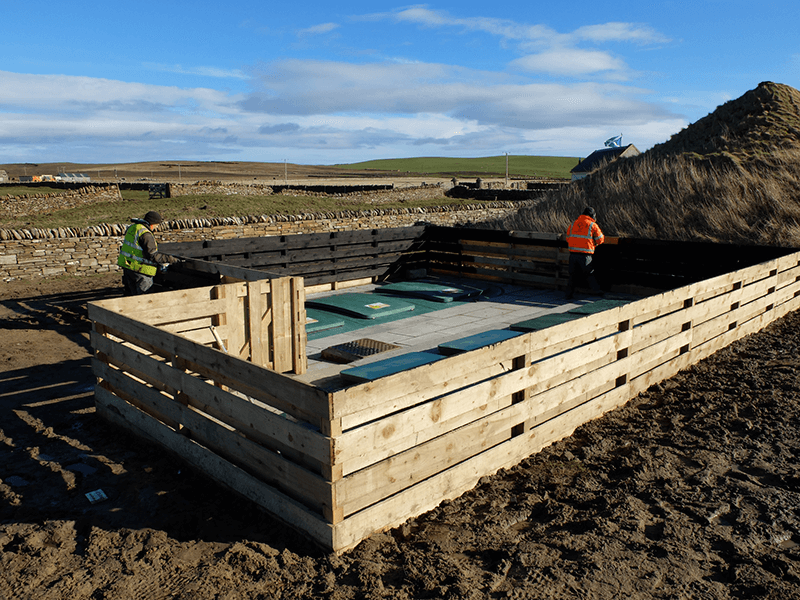

Compact & modular design options - to overcome site access and footprint restrictions

Scalable solutions to accommodate growing populations

*process guarantee is subject to correct installation, consistent influent conditions and regular plant maintenance as per the manufacturers’ instructions.

The HiPAF® range can typically attain: BOD 10mg/l: SS 10mg/l: Ammonia Nitrogen 2mg/l (with tertiary treatment), however higher NH 4-N and BOD 5 removal is achievable.

Phosphate removal is available with additional process technology design including chemical dosing

Animal waste - the HiPAF system combined with a sand filter and RADS is an ideal solution for animal centres

No odours due to a separate primary tank

No internal mechanical or electrical moving parts within the tank

Easier tankering - primary sludge and humus are stored together

Emptying of the tank not required during routine maintenance

Midi and Modular - rectangular tank shape reduces dead zones

Compact HPC CE marked to BS EN 12566-3 - ideal for a Site of Special Scientifiic Interest (SSSI)

Midi and Modular designed to BS EN 12255-1/15 and manufactured using BS 4994 as a guide

British Water’s Code of Practice - Flows & Loads

UK Building Regulations

Environmental Agency guidelines

Below ground installation do not interrupt the landscape views

Above ground installation – custom designed options

GSM telemetry available for remote monitoring of the plant

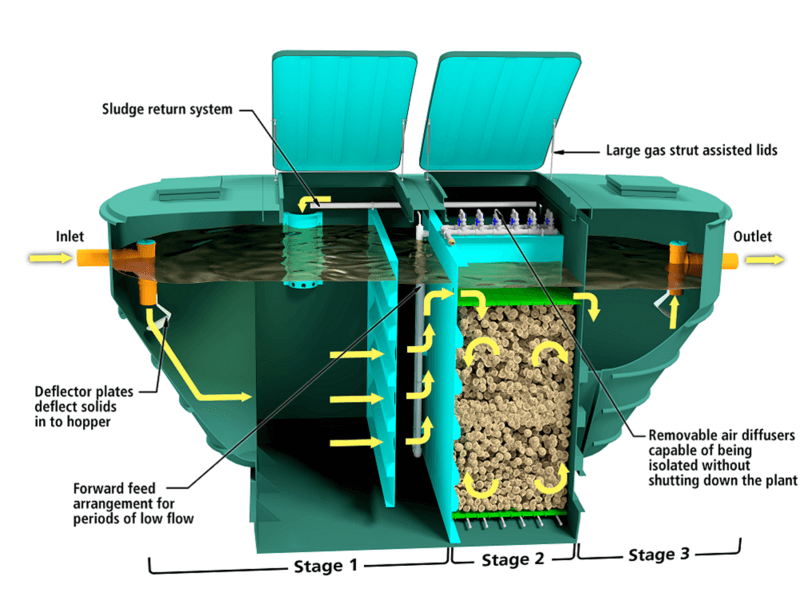

Midi and Modular lids

Commercial applications - lockable large gas strut lids

Water utility applications - MK3 lids with protective grate

Glass reinforced plastic (GRP) is UV stabilised with an external gel coat finish

UK manufacture in a quality controlled environment

Discreet HPC 1 up to 60 population equivalent - ideal for environmentally-sensitive areas

HiPAF® Midi sewage treatment plant does not impede on views

HiPAF® sewage treatment system with MK3 lids - installed by the highly regulated water utilities UK

Compliant to BS EN 12566-3

The compact HiPAF® HPC uses no chemicals during the treatment process and is ideal for locations which need extra consideration such as a burn, nature reserve, fisheries, salmon river or close proximity to water extraction (well).

The HiPAF® is also specified by the highly regulated UK water utilities and meets stringent European environmental discharge consent standards.

Warranty 25 years on the tank and standard air blower (housed in the kiosk) 2 years subject to correct installation, consistent influent conditions and regular plant maintenance as per the manufacturers’ instructions.

Each HiPAF® treatment plant includes a three-stage process – primary settlement, biological treatment (WCSEE Hybird™ biozone) and final settlement.

The segmented biozone process chambers eliminate the risk of process short-cuts and mitigates risks associated with variable loads.

The HiPAF® package sewage treatment plant is most appropriate for commercial and domestic applications where the site is not connected to mains drainage and is well suited to complex requirements, such as the treatment of animal waste.

The WCSEE sand filter is designed to remove excess suspended solids (SS) and biological oxygen demand (BOD) from a packaged sewage treatment plant and meets stringent discharge consent standards above what is normally expected from a biological process or an industry standard clarifier.

The produced sludge can be aerobically digested using our Robust Aerobic Digestion System (RADS) - deemed less of a risk to dispose of.

RADS is a cost efficient, low maintenance sludge treatment system which runs alongside the biological plant.

The HiPAF® with sand filter and RADS as a complimentary solution have been successfully installed at many animal centres such as kennels, catteries and stables.

WCSEE enhanced 310m ²/m³ neutral buoyancy (NB) plastic filter media is specifically designed for use with our patented Hybrid™ biological wastewater treatment process technology.

The NB Media supports the maximum surface area for the growth of bacteria in the filter bed whilst enabling the flow of water.

Power consumption and footprint

Does not require a scour cycle

Up to 65% reduced power consumption with the use of blower timer(s)

Less media is required in the Hybrid-SAF reducing footprint

310m ²/m³ absolute active surface area

High loading rates

Greater contact time with the effluent due to rotational flow

High protected surface for Biochemical Oxygen Demand , Nitrification and Denitrification

Greater protection - very slow media movement

Reduces abrasion associated with collision

Significantly reduces dead spots

Greater protection for exposed surfaces due to offset fins

Designed to be installed for the life span of the plant

Hire

New build

Repurpose

Refurbishment

Media can be sold loose

Manufactured in the UK

WPL (which is now a part of WCS Environmental Engineering) has been at the forefront of wastewater treatment technology for over 30 years, with international experience of technical design, quality of manufacture and supply of environmental wastewater solutions.

WCS Group forms part of Marlowe’s grouping of water and air industry – UK leader in specialist services that ensure safety and regulatory compliance.

We actively support our independent experts who provide installation, service and maintenance for packaged sewage treatment plants.

With nutrient neutrality requirements being enforced at off-mains properties in areas of England, homeowners need to ...

Why managing variable loads matters If you have an off mains wastewater treatment system operating at a hospitality, ...

Trade effluents are liquid waste streams discharged into public sewers from businesses and industrial processes. Their ...

Connect with WCS Environmental Engineering Safe Efficient Compliance

WCS Group is a trading name for WCS Environmental Ltd, registered in England and Wales (Number 02184649) at 20 Grosvenor Place, London, SW1X 7HN. Head Office – 17 Wheatstone Court, Waterwells Business Park, Gloucester, GL2 2AQ. WCS Group is a Marlowe Critical Services Company owned by Marlowe plc. 2025© WCS Environmental Ltd.