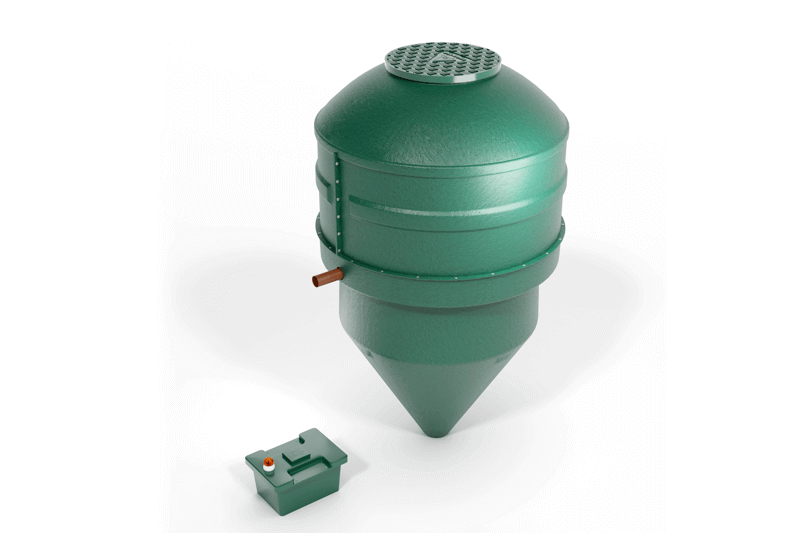

Formerly known as WPL Diamond

1 person up to 55 (people) occupancy equivalent

Suitable for domestic and small commercial properties in all ground conditions where mains drainage is unavailable.

Our discreet Diamond (formerly known as WPL Diamond) is better designed for modern day living than a septic tank system; with faster process and a more environmentally friendly result. There is no need for chemicals, allowing final effluent to be safely discharged to a a drainage field or watercourse.

25 years tank warranty and two years for the blowers*

Longer emptying cycle - up to 3 years desludge

Low maintenance

Fully compliant

Flushest lid to the ground – minimal visual impact

Made in the UK

*25 years warranty and two years for the blowers is subject to correct installation, consistent influent conditions and regular plant maintenance as per the manufacturers’ instructions.

Meets General Binding rules

- small sewage treatment plant

Fully compliant to BS EN12566-3

Effluent standard; as a minimum: 20mg/l BOD; 30mg/l SS; 20mg/l NH3

Additional published test results:*

Total ‘P’ mean average removal 52%, mean concentration 3.8mg/l

Total ‘N’ mean average removal 52.2%, mean concentration 25mg/l

Designed using British Water Code of practice flows & Loads

CE marked

* The additional Phosphorous and Nitrogen figures are taken from the Diamond EN 12566-3 test report covering 38 weeks in PIA GmbH, a European accredited test facility.

Can be installed in ‘wet’ or ‘dry’ ground conditions

Compact design, minimal excavation

Range of invert depths -

for complicated sites, allowing more discharge options.

UK and European patented

Glass reinforced plastic (GRP) is UV stabilised with an external gel coat finish

UK manufacture

Homeowners with septic tanks that discharge directly into the surface water will now need to consider the option of replacing with a packaged wastewater treatment plant, when selling a property or upgrading an ‘end of life’ septic tank.

Unlike the traditional septic tanks, the modern packaged wastewater (sewage) treatment plants such as a Diamond are designed with an aerated process for todays’ increased volume of water usage in everyday life.

%20kiosk800px.png?width=800&height=533&name=Diamond%20DMS%20with%20kiosk%20(hi%20res)%20kiosk800px.png)

Diamond DMS range 1 up to 20 occupancy equivalent

%20remove%20kiosk800px.png?width=800&height=533&name=Diamond%20DMC%20with%20kiosk%20(hi%20res)%20remove%20kiosk800px.png)

Diamond DMC range 21 upto 55 occupancy equivalent

Standard factory fitted body invert extension heights of 700mm or 1000mm.

For a shallow extension where the factory-fitted option is too great, a non-factory fitted neck invert extension (height is 460mm), can be supplied loose and cut to size on site.

If supplied with a factory-fitted invert and a deeper invert is required, please contact WCSEE or your supplier.

When on site and a deeper invert is required, you can order a 460mm invert neck extension which can be cut down to the required height. Only one 460mm extension can be fitted to the tank – do not stack with an additional turret. If in doubt please contact WCSEE for further installation advice.

The neck invert extension is supplied with:

450mm ½ PVC pipe

½” PVC sockets x2

Diffuser pipe support bar

Plastic push fittings for tree fixings x3

.png?width=800&height=533&name=External%20pump%20chamber%20(EPC).png)

The EPC also has the added benefit of being used as a sample chamber.

If a deeper factory-fitted invert extension is required, please specify on order.

The EPC comes supplied with:

Pump chamber x1

Manhole cover x1

High level float switch x1

Submersible pump and integral float switch x1

Non-return valve

Isolation valve

32mm MPDE pipe outlet fitting

Electrical junction box

Installation handles

Red, flashing high level alarm beacon as fitted on the kiosk

When on site and a deeper EPC invert is required – 215mm x 2 extension rings are available to order.

This is to accompany a non-factory fitted 460mm DMS neck extension.

Only one 460mm extension can be fitted to the tank – do not stack with an additional turret.

Standard factory fitted neck invert extension available in heights 300mm, 600mm,1000mm.

For a shallow extension where the factory-fitted option is too great, a non-factory fitted neck invert extension (height is 460mm), can be supplied loose and cut to size on site.

If supplied with a factory-fitted invert and a deeper invert is required, please contact WCSEE or your supplier.

The sample chamber is not a requirement; however, we recommend installing one for ease of access to retrieve samples.

The sample chamber comes supplied with 250mm removable inspection hatch x1.

%20extended.png?width=800&height=533&name=External%20pump%20chamber%20(EPC)%20extended.png)

The EPC also has the added benefit of being used as a sample chamber.

The EPC comes supplied with:

Pump chamber x1.Manhole cover x1

High level float switch x1

Submersible pump and integral float switch x1

Non-return valve

Isolation valve

32mm MPDE pipe outlet fitting

Electrical junction box

Installation handles

Red, flashing high level alarm beacon as fitted on the kiosk

EPC adapter kit additional part to accompany the Diamond DMS – EPC

Remote and rural site applications not connected to mains drainage:

Single house

Rural housing community

Outbuilding and barn conversion

Campsite, hotel and B&Bs

Commercial building, office and retail

Stately home and country estate

Septic tank replacement

New build and refurbishment

Original spare parts for the small Diamond package sewage treatment plant are available directly from our network of trusted independent experts or the manufacturer (WCS Environmental Engineering).

For further information, please send us an enquiry or contact us on +44 (0) 2392 242 600.

Domestic wastewater tends to originate from plumbing fixtures and appliances. This can include waste from toilets, dish washing, laundry, bath, shower, water softeners or other sources that cause an increased load or inhibit bacterial growth.

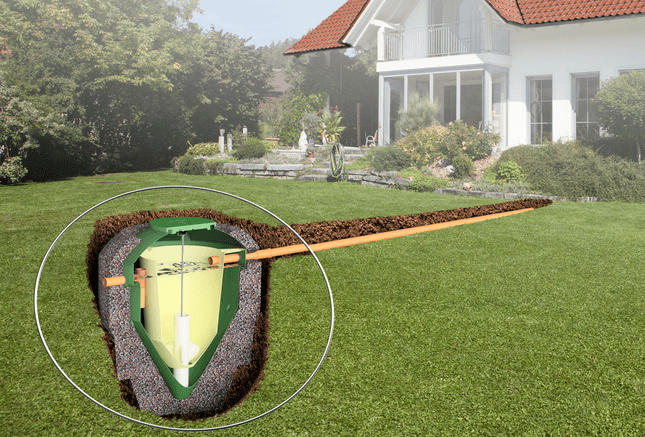

Our small Diamond package sewage treatment tanks are designed to sit below ground. The Kiosk can be installed above or below ground dependent on site conditions. A comprehensive installation manual is supplied with each plant, which you should read thoroughly prior to specification and installation.

We also recommend that you use an experienced and qualified installer. For further information, please send us an enquiry or contact us on +44 (0) 2392 242 600.

Please watch our installation video of the compact, domestic Diamond package wastewater treatment plant.

England

General binding rules state that your small sewage treatment system must meet the relevant British Standard in force at the time of installation. The standards currently in force for new systems are BS EN 12566-3 for small package sewage treatment plants.

Your small package sewage treatment plant meets the British Standard in place at the time of installation if: it has a CE mark; the manual or other documentation that came with your tank or treatment plant has a certificate of compliance with a British Standard; it’s on British Water’s list of approved equipment.

You can also ask the company that installed your equipment to confirm that it complies with the British Standard that was in place at the time the equipment was installed.

Diamond - all of the plants within our domestic package sewage treatment range will be eligible to apply for an exemption as long as they do not exceed 5m3 per day to water course or 2m3 per day to a drainage field.

The EA will inform applicants if they are not eligible for a registration and therefore require a permit.

Scotland

If you have a small package sewage treatment plant on your property in Scotland, it must additionally be registered with the Scottish Environment Protection Agency (SEPA). This must be presented when a new property is being built or an existing property changes hands. For further information, please contact the Scottish Protection Agency.

Wales

If you have a small package sewage treatment plant on your property in Wales, it must additionally be registered with Natural Resources Wales. For further information, please contact Natural Resources Wales.

Ireland

For further information, please contact Ireland Environment Protection Agency.

The treated final effluent from your package sewage treatment plant can be discharged in to a water course or a drainage field with Environmental Agency approval.

Please check your local environment agency (England, Scotland, Wales and Northern Ireland) for regulations.

The high quality Diamond range is CE marked, fully type tested and certificated in accordance with the mandatory European standard BS EN12566-3 2014 for small wastewater treatment systems. Performance tested at an independent accredited facility in Aachen, Germany by PIA Institute for Wastewater Technology.

A drainage field has two main purposes:

To allow infiltration of the partially treated effluent into the ground at a controlled rate.

To allow further natural biological treatment of the partially treated effluent before it reaches the underlying groundwater. This treatment takes place in the aerated layers of the soil. A suitable percolation test will ensure that the receiving ground is suitable for the installation of a drainage field.

It is essential that as an owner of a Packaged Wastewater Treatment Plant you do not inadvertently agree to have a soakaway installed, which should only be used with surface water, not with wastewater.

A poorly maintained or incorrectly installed drainage field will result in environmental pollution and owners may be subject to enforcement by the environmental regulator.

Owners must ensure their Packaged Sewage Treatment Plant been correctly installed and complies with the current building and environmental regulations.

England - Environment Agency Building Regulations (Part H-H2 Package Sewage Treatment Works) state that all sewage treatment plants should be sited 7m-10m from any inhabited part of the property. The building control officer for the site will make the final decision on exactly how far the plant should be sited. If the discharge is to a drainage field a sampling chamber must be provided before the drainage field. Drainage field drains must be constructed in the aerobic soil layer, i.e. within 700mm of ground level. Please visit your local Planning Portal website for further information.

Please check your local environment agency (England, Scotland, Wales and Northern Ireland) for regulations.

If the location of the Diamond plant is on an incline, in a highwater table area or a long distance away from the designated discharge point (ie: a drainage field/water course/ditch) the final effluent may require pumping.

The Diamond range can be specified with an EPC which can deliver up to 100 litres per minute of effluent at a head of 4m. The external pump chamber (EPC) can be simply retro-fitted and is easy to maintain.

Your newly installed sewage treatment plant can be used immediately! The biological process can take between 6-8 weeks to start working.

A percolation test is required for a drainage field to assess how much water can drain away through the subsoil. This is performed by an experienced site surveyor who excavates a small area of subsoil to monitor. We advise this test is taken prior to a package sewage treatment plant being installed.

This can be determined by digging a trial hole and leaving it open for 48 hours for a site assessment.

If you would like to request a visit from an independent expert in order to carry out this assessment, please make an enquiry or contact us on +44 (0)23 92242 600.

Please check your local environment agency (England, Scotland, Wales and Northern Ireland) for regulations.

According to the Environment Agency in England, if you sell your property, the new owner must be informed of your package sewage treatment plant in writing. The information in your writing must include: a description of the treatment system and drainage system; the location of the main parts of the treatment system, drainage system and discharge point; details of any changes made to the treatment system and drainage system; details of how the treatment system and drainage system should be maintained, and the maintenance manual and records if you have them.

Please check your local environment agency (England, Scotland, Wales and Northern Ireland) for regulations.

Flows and Loads is the Sizing Criteria, Treatment Capacity for Small Package Sewage Treatment Plants. This code of practice was prepared by the British Water Package Sewage Treatment Plant Focus Group comprising manufacturers, suppliers and service companies of all types of small wastewater treatment systems.

Loading tables

This code of practice provides a table of loadings which allows the total daily sewage load from properties to be calculated and it is recommended that all designers should use this table when sizing and designing non-mains sewage treatment systems. The flows and loads values given represent current best knowledge within the UK but may change with time in line with per capita water use.

The Diamond sewage treatment range is designed using the British Water code of practice flows and loads, to ensure the tank is sized correctly.

Unlike the traditional septic tanks, modern package sewage treatment plants are designed with an aerated process for todays’ increased volume of water usage in everyday life.

Septic tank: Typically, a septic tank is found underground, receiving untreated sewage from a property and allowing the heavier solids to settle at the bottom whilst the effluent rises to the top. Naturally occurring bacteria helps the system break down the solids and sludge, with the remaining liquids flowing out of the tank into a drainage field. Septic tanks only provide partial treatment: settlement and separation of the solid waste and will normally discharge to a sub-surface soakaway or ditch.

Small package wastewater treatment plant: On the other hand, a small package sewage treatment plant provides significant biological breakdown of the organic and chemical contaminants by using air to circulate and treat the contaminants to a much higher standard than a septic tank. Package sewage treatment systems “clean” the wastewater significantly, which permits effluent discharge into less porous soils,effluent can then be discharged into a water course, drainage ditches and a a drainage field. Please check your local environment agency (England, Scotland, Wales and Northern Ireland) for regulations.

The Diamond small package sewage treatment plant has an added advantage of a high quality process in a compact, single tank which is easy to install and maintain. The successfully treated liquid that is discharged from the Diamond sewage treatment plant is of a higher quality standard than a septic tank. This means that our wastewater treatment plant will help to prevent your a drainage field from blocking. If discharging in to a running water course, our sewage treatment plant can help to reduce your environmental impact.

WPL (which is now a part of WCS Environmental Engineering) has been at the forefront of wastewater treatment technology for over 30 years, with international experience of technical design, quality of manufacture and supply of environmental wastewater solutions.

WCS Group forms part of Marlowe’s grouping of water and air industry – UK leader in specialist services that ensure safety and regulatory compliance.

We actively support our independent experts who provide installation, service and maintenance for packaged sewage treatment plants.

With nutrient neutrality requirements being enforced at off-mains properties in areas of England, homeowners need to ...

Why managing variable loads matters If you have an off mains wastewater treatment system operating at a hospitality, ...

Trade effluents are liquid waste streams discharged into public sewers from businesses and industrial processes. Their ...

Connect with WCS Environmental Engineering Safe Efficient Compliance

WCS Group is a trading name for WCS Environmental Ltd, registered in England and Wales (Number 02184649) at 20 Grosvenor Place, London, SW1X 7HN. Head Office – 17 Wheatstone Court, Waterwells Business Park, Gloucester, GL2 2AQ. WCS Group is a Marlowe Critical Services Company owned by Marlowe plc. 2025© WCS Environmental Ltd.