The Dissolved Air Flotation (DAF) water treatment process is a physical and chemical technology for the effective removal of biological solids from a wide range of wastewaters to maintain environmental compliance and reduce trade effluent charges.

DAF systems are designed to reduce total suspended solids (TSS), biochemical oxygen demand (BOD), and fats, oils and greases (FOG) from a wastewater stream.

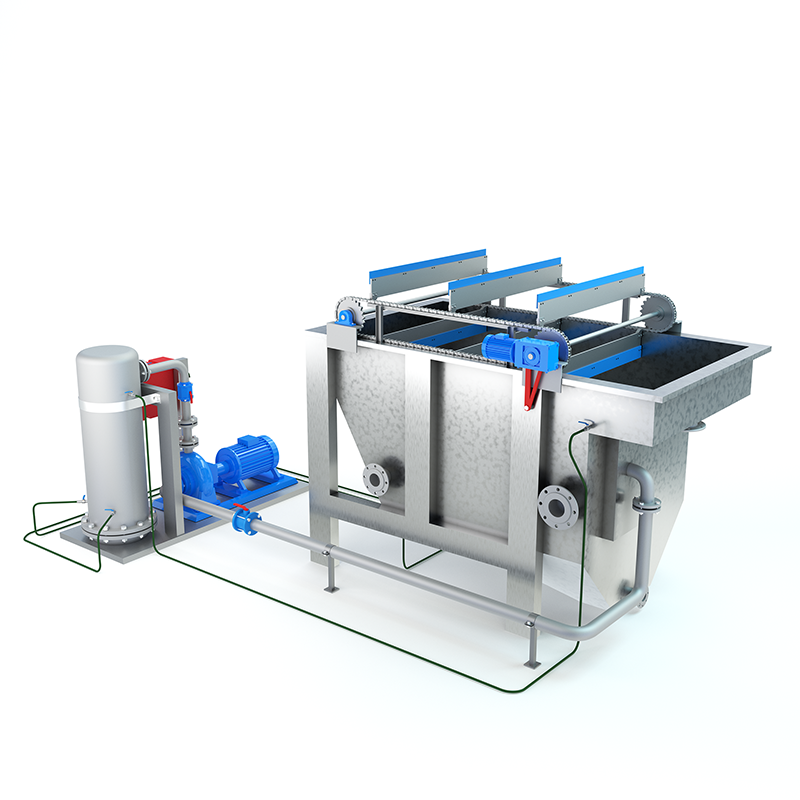

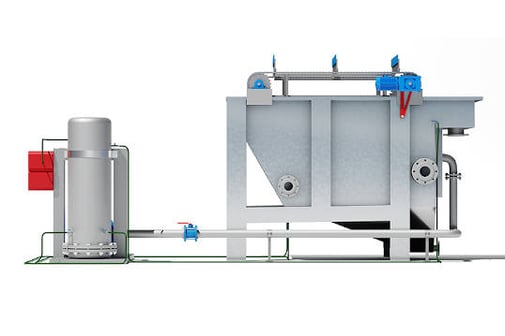

The highly refined DAF system mixes air and pressurised water, which forms micro-bubbles that adheres to flocs of suspended material coagulated by chemicals and creates a floating bed of sludge to be removed, leaving clean final discharge water.

Fully automated control system, reduces the need for manual operation

Flexible process that be can adjusted in-situ

Easy to install compact design with a small footprint

Energy efficient treatment of wastewater

Chemical regime optimised for use with our technologies

White water system utilises a saturation vessel to negate the need for diffusers within the floatation tank

Can be used for recovery and recycling of non-emulsified oils with no further treatment required

Higher quality effluent discharged to sewer further reducing trade effluent charges

Sludge often suitable for Anerobic Digestion disposal route

Stainless (304 or 316) plus reinforced plastic components reduce wear and corrosion

Purpose build, adaptable flocculation system to allow ideal sampling, pH correction and dosing

Can be linked with Screening and Sludge Dewatering for even higher efficiency

Can be integrated with site SCADAR and BMS (building management systems)

Multiple systems can be installed in parallel for higher or variable flows

Multiple chemical injection and sampling points to site requirement

Containerised or skid mounted for temporary solutions – trial and hire options

WCS Environmental Engineering offers full commissioning and training to customers with annual service contracts

Container DAF

Skid mounted DAF

Specialist in wastewater and trade effluent solutions to help bring your site into consent.

The system is a physical process enhanced with chemical dosing which operates on a simple design philosophy. Incoming effluent can be screened to increase solids and COD reduction.

Adjustment of pH may also be necessary to ensure optimum operating conditions.

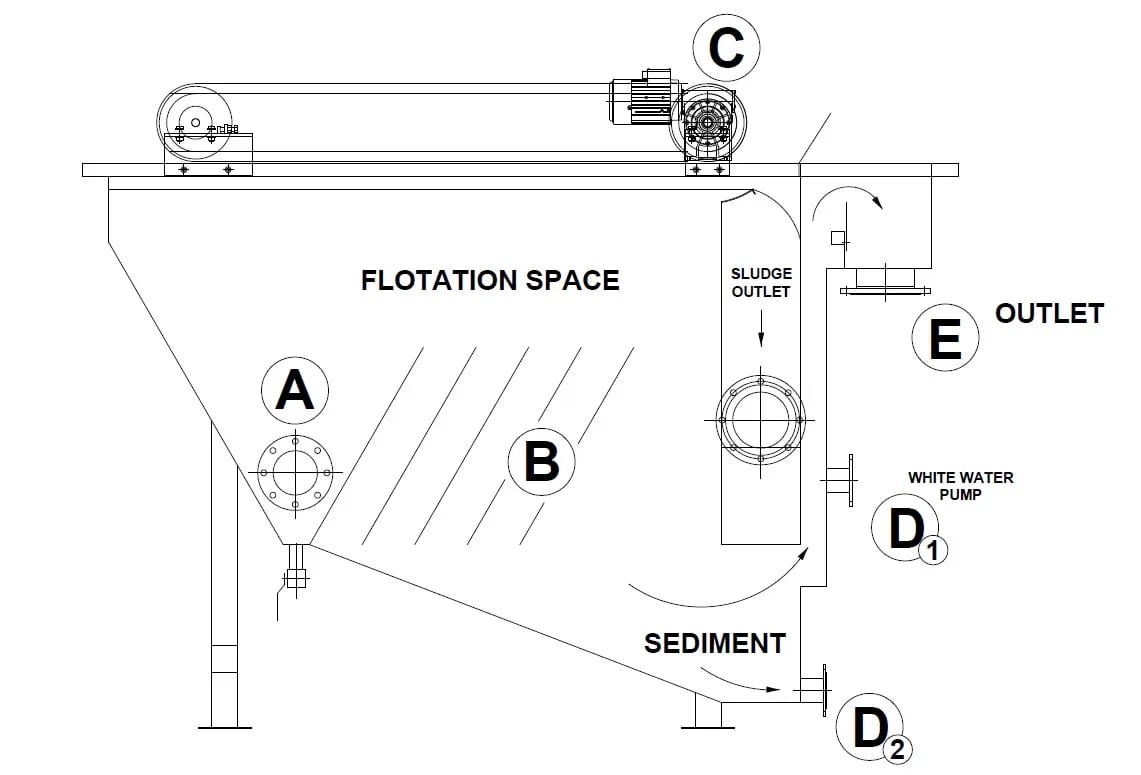

The effluent flows through the flocculator to be pH corrected and dosed with a coagulant and flocculant, entering the DAF cell and mixes with white-water (a combination of air and water mixed under pressure to form micro-bubbles.

As the white-water and effluent mix, the micro-bubbles attach to the colloidal matter and chemical flocculants within the effluent, and move together forming larger flocs that float to the DAF surface.

The surface skimmer uses paddles to push the floating flocs (sludge) into the sludge hopper to be removed and sent to a separate sludge tank. The paddles have adjustable speeds or dwell times to reduce water entering the sludge hopper.

As the flocs float, the solids free water is pushed down to the middle of the DAF cell, ready to be saturated back into white-water. This gives the DAF a constant supply of clean white-water without the expense of adding fresh potable water to the system.

Where solids normally sink (sand, grit etc), they collect in the hopper and are removed via a manual or automated valve, dependent on the effluent.

The final treated “clean” effluent discharges to either drain or for further treatment.

Food and Beverage such as

abattoir

diary

consumer food and beverage products

raw agricultural goods

Waste management and remediation services

Personal care and cosmetics

Pharmaceutical

Aggregates and raw materials

Chemicals manufacture

Metal finishes, mining and quarrying

Automotive

Fish farms and livestock manure

Machinery manufacturing and metal processing plants

Paper mill and glass factories

With nutrient neutrality requirements being enforced at off-mains properties in areas of England, homeowners need to ...

Why managing variable loads matters If you have an off mains wastewater treatment system operating at a hospitality, ...

Trade effluents are liquid waste streams discharged into public sewers from businesses and industrial processes. Their ...

Connect with WCS Environmental Engineering Safe Efficient Compliance

WCS Group is a trading name for WCS Environmental Ltd, registered in England and Wales (Number 02184649) at 20 Grosvenor Place, London, SW1X 7HN. Head Office – 17 Wheatstone Court, Waterwells Business Park, Gloucester, GL2 2AQ. WCS Group is a Marlowe Critical Services Company owned by Marlowe plc. 2025© WCS Environmental Ltd.