We’re on LinkedIn!

Connect with WCS Environmental Engineering Safe Efficient Compliance

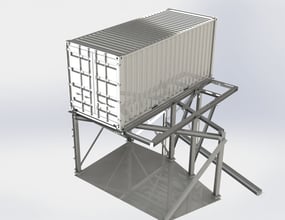

A custom designed wastewater treatment plant, cantilevered above ground level, has been created for Islington London council waste recycling centre.

Due to the tight physical footprint on site, the 6m-long containerised package plant is raised 2m above the site access and 6m above the vehicle parking area, which is at a lower level. The side-opening container is half-suspended on a frame comprising more than 10 steel I-beams.

The limited site space made it necessary for a full-length platform for operations and maintenance to be fitted alongside the plant, allowing full access for safe working at height. The whole installation was painted to blend in with existing buildings as the site is overlooked by residential properties.

Simon Kimber, Sales Director said: “This is one of the most unusual designs the company has ever developed. However it is backed with decades of experience of how to create a treatment plant which is reliable, robust and effective."

We beat eight competitors to win the final contract and the innovative package plant design was developed by the company’s in-house engineering team. Our engineers have a detailed understanding and experience of how equipment can be adapted to different sites.

Kimber said: “Along with the extremely tight footprint, this is also among the hardest-to-treat effluent our engineers have ever had to deal with. All the black bin bags from a large area of a London are collected at this site and compressed.

“The run-off from the bin bags is highly variable and contains very high levels of a range of pollutants.”

Previously the run-off from the solid waste plant was discharged into the public sewers – however the council was keen to avert any risk of breaking consent levels set by Thames Water. The council was also having to pay increasingly high quarterly sewerage charges in accordance with the Mogden Formula, which sets fees for the disposal of trade effluent based on volume and the level of biological oxygen demand (BOD).

Kimber said: “One of the things that made this job challenging was the unknown composition of the black bag run-off. Household waste can contain a huge variety of substances, including animal products, medicines, chemicals, oils and food waste.”

We have particular expertise in handling hard-to-treat effluents. The company’s engineers visited the London siteand took samples to ascertain what sort of substances a tailor-made wastewater treatment plant would need to process.

Effluent samples were taken to the laboratory for in-house testing. The samples were then subjected to a range of different processes to assess their treatability with biological, physical and chemical processes.

Testing showed of 14,600mg/l chemical oxygen demand (COD), 12,300mg/l suspended solids, 325mg/l ammonia, 45mg/l phosphorus and 915mg/l oil and fats. Once the levels of pollutants had been tested in the lab, We carried out an onsite trial to ascertain how various treatment options would work in practice.

Kimber said: “The trial is absolutely key to finding the right combination of treatments needed to handle hard-to-treat effluent. By adjusting the balance of physical, chemical and biological treatments it is possible to achieve excellent results, even with very difficult effluents.”

We specialises in treating challenging effluents from a variety of industrial processes. The company has successfully treated effluent from a blood processing plant, from fish farms and waste from an abattoir and zoos.

In the case of the London waste recycling centre, our engineers carried out a week-long pilot study, diverting a quarter of the effluent and treating it with various biological, physical and chemical processes.

Kimber said: “It is one thing to carry out tests in laboratory conditions, but quite another to treat effluent on site. By carrying out onsite testing, we ensure the specified treatment process will do everything it needs to do and can handle variations in flow and levels of pollutants.

“In this case the trial had to be carried out while the waste disposal plant was still in operation.”

The treatment plant uses a specially developed formula of chemical treatments to drastically reduce COD levels in the effluent. A sludge thickening coagulent treatment has also been included to reduce the amount of sludge tankered off site.

The plant has been adapted from our standard Dissolved Air Flotation (DAF) system by adding a number of additional chemical and physical treatment stages in order to deal with the unusually strong effluent being treated.

Initial testing suggests the treatment has exceeded expectations.

Treated effluent now has COD at less than 350mg/l, settled solids of 0.1 per cent, ammonia levels of less than 5mg/l, less than 2mg/l of oil and fat and phosphate levels of less than 3mg/l. The effluent has also been tested for thiourea, a chemical used in a wide range of industrial processes, which is down to levels of less than 2mg/l.

Kimber said: “The levels of pollutants involved could vary on a daily basis and space on the site was extremely tight.

“The cantilevered design our engineers created is extremely ingenious and was largely manufactured off-site, which reduces the health and safety risk during installation. Combined with our DAF treatment system it was the ideal solution for the London waste recycling plant.

“This project shows the importance of running a trial when dealing with hard-to-treat trade effluent. The good news for other local authorities is that we are now confident we have designed a wastewater treatment process specifically tailored to deal with the enormous range of pollutants found in the run-off from household waste.

“Sewerage charges are rising all the time and there must be many other waste disposal facilities around the country which are experiencing similar problems.”

With nutrient neutrality requirements being enforced at off-mains properties in areas of England, homeowners need to ...

Why managing variable loads matters If you have an off mains wastewater treatment system operating at a hospitality, ...

Trade effluents are liquid waste streams discharged into public sewers from businesses and industrial processes. Their ...

Connect with WCS Environmental Engineering Safe Efficient Compliance

WCS Group is a trading name for WCS Environmental Ltd, registered in England and Wales (Number 02184649) at 20 Grosvenor Place, London, SW1X 7HN. Head Office – 17 Wheatstone Court, Waterwells Business Park, Gloucester, GL2 2AQ. WCS Group is a Marlowe Critical Services Company owned by Marlowe plc. 2025© WCS Environmental Ltd.