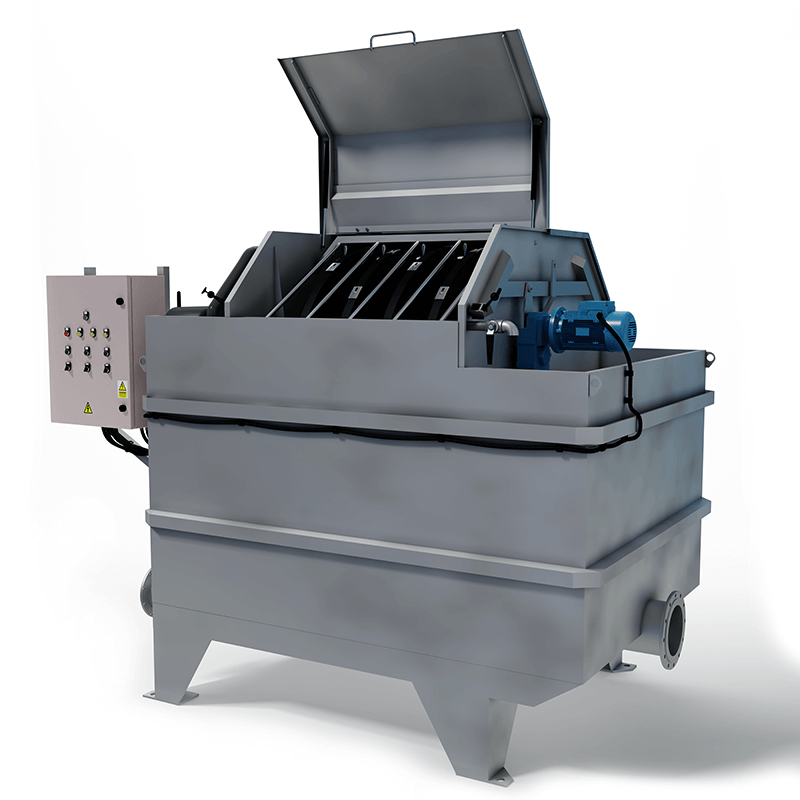

Designed for tertiary filtration (effluent polishing) of large volumes of wastewater, the compact system has the capability to filter high flows (volumes) of liquids.

Low power consumption – gravity flows save energy costs

Enables filtration from 10μm up to 200 μm mesh size

Compact unit with a high filtration quality that delivers high flows up to 500 L/s

Process can be used to assist with achieving Fe & P compliance

Filtration runs continuously without interruption

Simple removal and replacement of filter cartridge

Suitable mainly for tertiary filtration treatment removing undissolved material

Fully automatic operation with programme pre-set operation parameters

Units can be put into operation immediately after installation

Installed above ground in steel tanks

Installed below ground in concrete channels

Skid mounted options for temporary solutions – hire and trial

Industrial processes

Biologically treated wastewater

Pre-treatment before Ultraviolet (UV)

Pre-treatment of potable water

Cooling water

Inlet process water

With nutrient neutrality requirements being enforced at off-mains properties in areas of England, homeowners need to ...

Why managing variable loads matters If you have an off mains wastewater treatment system operating at a hospitality, ...

Trade effluents are liquid waste streams discharged into public sewers from businesses and industrial processes. Their ...

Connect with WCS Environmental Engineering Safe Efficient Compliance

WCS Group is a trading name for WCS Environmental Ltd, registered in England and Wales (Number 02184649) at 20 Grosvenor Place, London, SW1X 7HN. Head Office – 17 Wheatstone Court, Waterwells Business Park, Gloucester, GL2 2AQ. WCS Group is a Marlowe Critical Services Company owned by Marlowe plc. 2025© WCS Environmental Ltd.