Ideal for dewatering difficult sludges of dissolved air floatation (DAF) and biological (aerobic and anaerobic) sludge and raw effluent flows that are prone to clogging traditional filter materials, especially those with;

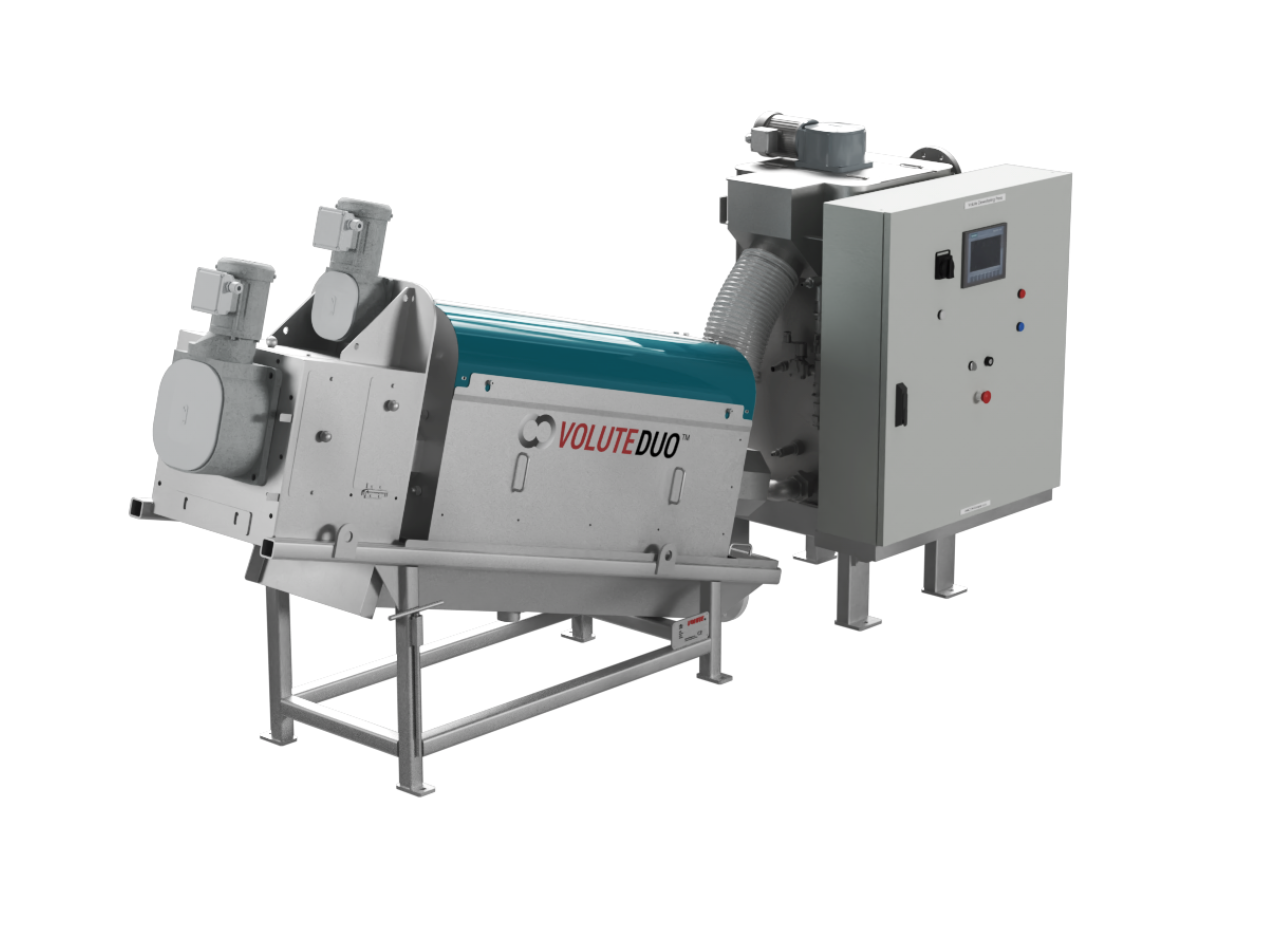

The Volute DUO offers all of the advantages of the Volute FS screw press range but features twin counter-rotating screws within a single drum to break up and move materials that typically bind and harden during pressing.

This design enables full mechanical dewatering and thickening of even the most difficult sludges without compromising performance or risking operational failure.

Reduces power consumption of dry solids by up to 90% compared to a centrifuge

Handles sludge as dilute to 0.5% TS

No pre-thickening required

Uses up to 95% less rinsing water compared to a belt press and a centrifuge

Reduces the cost of sludge dewatering by over 50%.

Very low maintenance - no moving rings contact within the Duo

Expandable controls to link to external tanks, conveyers, waste bulkers technologies

Adjustable CIP systems to auto- clean between batches or low levels

Self-cleaning filter for stable and constant dewatering

Low maintenance and operator interaction with automatic stop/start

Chemical regime optimised for use with our technologies

Duo can incorporate PH correction if required

Specialist in wastewater and trade effluent solutions to help bring your site into consent.

The Volute Duo Screw Press is designed to efficiently dewater sludge while overcoming the clogging and maintenance issues found in traditional screw presses.

Unlike conventional designs that rely on fixed openings, which can become blocked with solids over time, the Volute Duo Screw Press features a self-cleaning mechanism. Its alternating fixed and moving rings continuously clean the fine gaps, ensuring consistent water release and preventing blockages. This allows for a more compact and efficient press, reducing the need for oversized equipment while maintaining high dewatering performance.

A key advantage of the Volute Duo Screw Press is its friction-less operation, where the moving rings are guided by an external drive mechanism, preventing direct contact with the screw. This eliminates wear points, greatly extending the lifespan of consumable parts and reducing maintenance requirements.

Additionally, the system operates at a low screw rotation speed (2–4 RPM), resulting in significantly lower energy and much reduced water consumption compared to alternative dewatering technologies. The fully enclosed design further enhances performance by minimizing odours and noise, making it an ideal solution for facilities requiring reliable, cost-effective, and low-maintenance sludge treatment.

Abattoir

Diary

Consumer food and beverage products

Raw agricultural goods

Waste management/remediation services

Personal care and cosmetics

Pharmaceutical

Aggregates and raw materials

Chemicals manufacture

Metal finishes, mining and quarrying

Automotive

Fish farms and livestock manure

Machinery manufacturing/metal processing plants

Paper mill and glass factories

With nutrient neutrality requirements being enforced at off-mains properties in areas of England, homeowners need to ...

Why managing variable loads matters If you have an off mains wastewater treatment system operating at a hospitality, ...

Trade effluents are liquid waste streams discharged into public sewers from businesses and industrial processes. Their ...

Connect with WCS Environmental Engineering Safe Efficient Compliance

WCS Group is a trading name for WCS Environmental Ltd, registered in England and Wales (Number 02184649) at 20 Grosvenor Place, London, SW1X 7HN. Head Office – 17 Wheatstone Court, Waterwells Business Park, Gloucester, GL2 2AQ. WCS Group is a Marlowe Critical Services Company owned by Marlowe plc. 2025© WCS Environmental Ltd.